Show Us What You’re Made of

Amazing materials being developed in Berlin.

Everything is made of something. In production as well as design, the choice of material is of the essence. Research and experimentation with new compounds and sources of material is bringing about technological advances, for instance in robotics. And with researchers finding 2000 particles of microplastics to a cubic meter of seawater, it is clear that certain materials pose significant problems. In Berlin, many new materials are being explored and developed as alternatives to plastics.

Amazing Use Cases

There are cases in which the use determines the material. Surgical gloves worn by medical staff protect against infection, but are prone to needle puncture. Sometimes doctors wear two sets of gloves on top of one another for safety, but of course this reduces dexterity. The company Smarterials Technology has been well-funded to develop the world’s safest surgical gloves with higher puncture resistance and change of color where a needle pricks. The company is based in the Technology Park Berlin Adlershof, right next to the world renowned Helmholtz center for materials and energy (HZB).

A less niche use case than surgical gloves is packaging. Packing material accounts for one third of plastics produced. The company Mujolab is working on a material that disappears after it has served its purpose, the idea being that durable materials need not be used for short-life use. Their packaging is made of algae, more specifically kelp, which bio-degrades when thrown away. Kelp grows incredibly fast in underwater ‘forests’ and is easily harvested.

Even more like science fiction is MotorSkins, who make reactive textiles “that come to life”, meaning soft-robotic fabrics which can be used as “active garments that function as external muscles” because they contain embedded fluids. The use cases here are manifold, from thermoregulating cooling vests and thrombosis-preventing medical socks to VR gloves, or more intuitive and efficient interfaces between humans and machines with morphing haptic surfaces.

Amazing Materials

Research at the Technical University Berlin is exploring the applications of mushrooms. A team of around 50 people in the applied and molecular microbiology research laboratories have already presented, among other things, organic fungus-based bricks, fire-resistant insulating materials, and substitutes for polystyrene in bicycle helmets. The aim is to supplement the circular economy with fungal biotechnology.

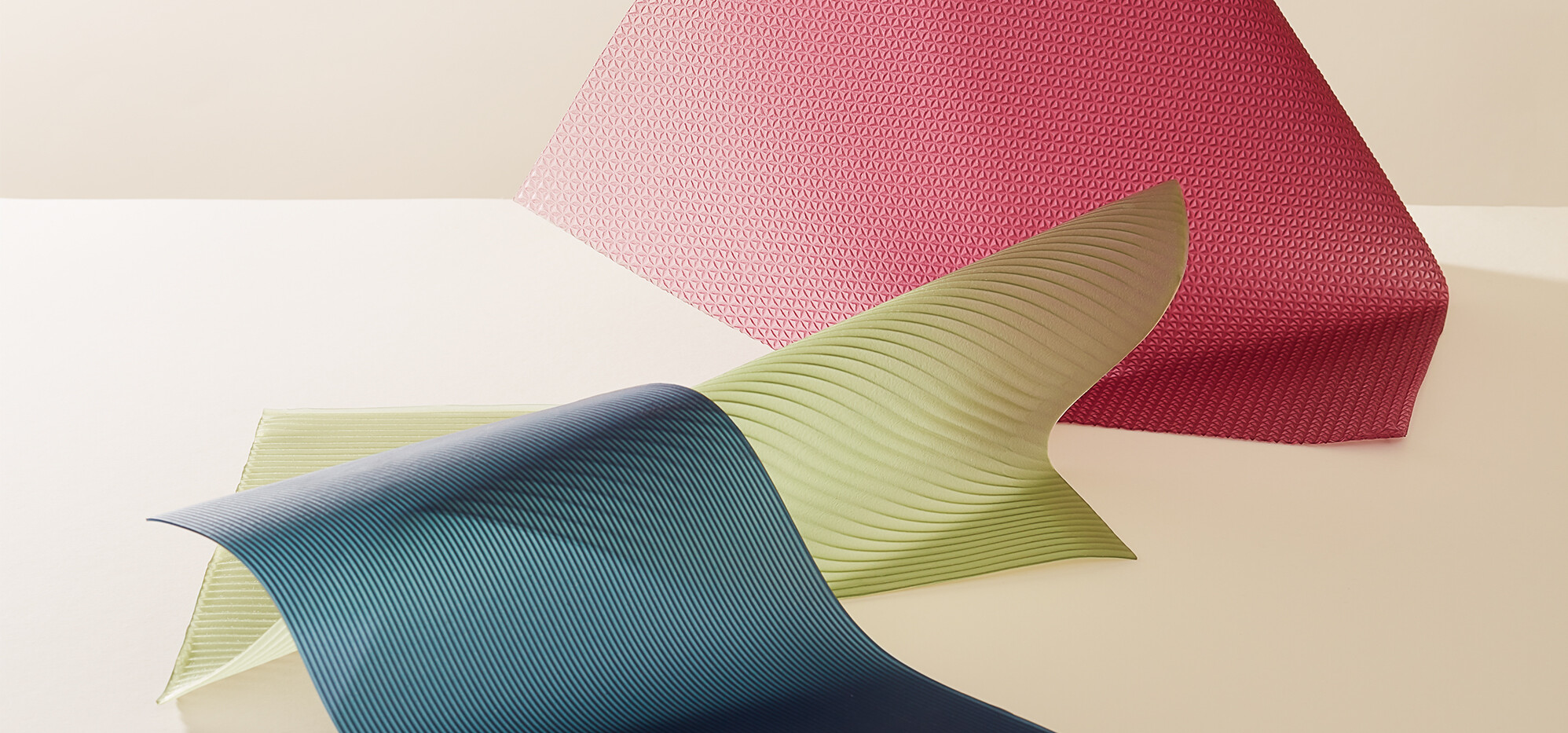

Nothing comes from nothing, and a way of creating sustainable alternatives to plastic is to use waste materials effectively. For instance, orange peels. Through a process of grinding, blending, and forming, Peelsphere recycles fruit peels into a soft and waterproof material that can be knitted, woven, embroidered, or 3D printed. As an alternative to leather or synthetic leather, Peelsphere materials are durable, versatile, and biodegradable. Designers the world over, from fashion to architecture, are fascinated by the possibilities these new materials offer.

Instead of incinerating non-food biowaste, Made of Air turns organic matter from agricultural and forestry waste such as wood chips, leaf litter, or dead plants into biochar, which is elemental carbon that locks in its CO2 content. This material can be used as filler, mixed with other binders to create carbon-negative compounds. This carbon capture method prevents re-emission of CO2. At end of life, products using Made of Air filler material – for instance in mobility, logistics, or consumer goods – can be “returned to the earth safely either directly or as biochar.”

Amazing Benefits

Another Berlin company that has dedicated itself to removing CO2 from the atmosphere is Meloon. The founders believe that “we need many carbon dioxide removal solutions working together to keep global heating to safe levels.” Unlike carbon removal tech that relies on cleaning combustion gasses with chemical solvents, Meloon separates the molecules from each other with a porous material that acts like a filter. The team is working on nanoporous graphene membranes for post-combustion separation, a very promising technology that overcomes the energy and cost problems of solvent-based purification technology. Atom-thin graphene is used as material for this advanced separation process.

At Ucaneo they are developing the world’s first biomimetic direct air capture technology, which uses a biocatalytic membrane made of synthetic biological material to capture CO2 from the air. Next to an office in the heart of Berlin, they have two labs, the main one at Campus Buch and one at IRIS Adlershof, one of the leading labs in Europe for hybrid materials with the Helmholtz Institute and HU Berlin.

Finally, nanotechnology startup Mimotype is developing novel material systems for bio-inspired organic semiconductor technology that will enable light generation modeled on bioluminescent marine life. Their advantage: In contrast to current LED light sources, whose production requires rare earths and heavy metals, so-called OLEDs (organic light-emitting diodes) are considered to be a more sustainable as well as a more health-friendly successor technology.

One of the drivers of innovation in the field of materials technologies is the Innovation Network for Advanced Materials (INAM), a non-profit association that aims to accelerate the global market entry of technological innovations by enabling collaboration between startups, companies and research institutions. INAM’s activities include AdMaLab and AdMaCom. AdMaCom is the Advanced Materials Competition, a fast-paced 3-week accelerator program for advanced materials startups and scaleups from around the world, held twice a year in Berlin. AdMaLab is a 6-month incubation program in cooperation with Humboldt University for entrepreneurs and researchers looking to commercialize new materials science ideas from the laboratory. Among many others, Meloon and Ucaneo have participated in AdMaLab.

At the bleeding edge between science and commerce, Berlin researchers and startups are developing today the materials we’ll take for granted tomorrow.

See also our article on additive manufacturing.

Text: Olaf Bryan Wielk, ideenmanufaktur

Header image: © Peelsphere